Service

Home

>Service

Customised Service

We provide customised solutions, personalised design and production according to customers' needs and requirements, providing tailor-made silicone products for customers.

High Temperature Resistance: Silicone products have excellent high temperature resistance and are suitable for various high temperature environments.

Good Elasticity: Excellent elasticity and softness, able to adapt to a variety of complex shapes of the design needs.

Environmental Protection And Safety: Using food-grade silicone raw materials, non-toxic, tasteless, non- polluting, in line with environmental requirements.

Wear-Resistant And Corrosion-Resistant: Excellent wear-resistant and corrosion-resistant, not easy to be deformed or damaged in long-term use.

Diversified Applications: Customized silicone products of various shapes, sizes and colours according to customers' needs, with a wide range of applications.

Silicone Products Factory Advantage

The company can meet the diversified customized needs of customers, as well as large

size, large quantities of silicone products supply..

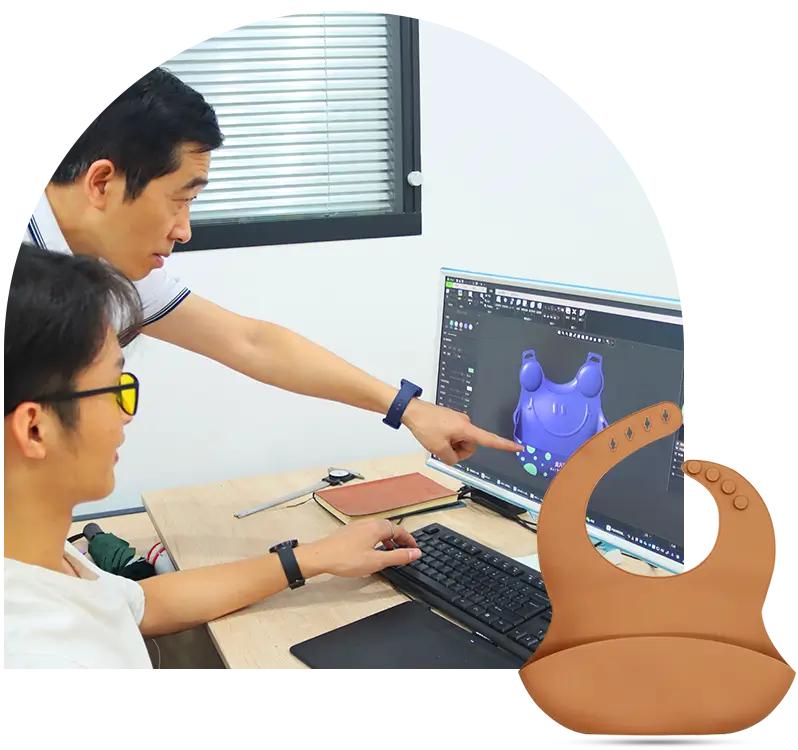

Technical Strength

We have an experienced and skilled R&D team.

Production Capacity

Advanced equipment and perfect production lines, able to meet the demand for large-volume orders.

Quality Assurance

Strict quality management system to ensure that the products meet international standards.

Customer Service

Professional customer service team, timely response to customer needs, provide customised solutions.

Innovation Ability

Continuous technological innovation and product upgrading to maintain competitive advantage.

Historical Process

Year of Establishment: Dibo factory was established in 2011.

Initial Stage: At first, we were mainly engaged in precision sealing ring moulds and production services, and accumulated rich experience in the industry.

Technological Breakthrough: Through continuous technological development and innovation, we successfully broke through the moulding production and post-process improvement, and gained industry recognition.

Market Expansion: With the improvement of product quality and popularity, Dibo has gradually expanded its market share and established cooperative relationship with more brand customers.

Development And Growth: So far, Dibo has developed into a benchmark enterprise in the local industry, constantly improving product quality and service levels, and is committed to providing customers with better quality silicone product solutions.

Technical Breakthroughs And Product Improvements

In the early stage of development, Dibo continuously carries out technical research and development and innovation, and is committed to solving the difficult technical problems and product bottlenecks in the industry. Through continuous efforts, we have successfully broken through the moulding production and post-processing improvement of moulding production and post-processing improvement, thus improving the product quality and performance, and won the recognition and praise of the market.

Market Expansion And Customer Relationship Building

With the improvement of product quality and popularity, Dibo began to actively explore the market, expanding sales channels and expanding product coverage. By participating in industry exhibitions and carrying out marketing and promotional activities, we have actively expanded our customer base, established a solid relationship with more customers, and formed a good customer reputation and reputation.

Continuous Development And Growth Stage

With the intensification of market competition and the constant changes in customer demands, Dibo continuously adjusts and optimises its product structure, strengthens its internal management, and improves its production efficiency and product quality. Through the introduction of advanced production equipment, recruitment of high-quality personnel, strengthening cooperation with partners and other measures, we continue to strengthen the core competitiveness of the company, achieve sustained and steady development, and become one of the benchmark enterprises in the industry.

Future Outlook And Development Goals

In the future, Dibo will continue to adhere to the "quality first, solid development" business philosophy, and constantly improve product quality and service level, increase technological innovation and R & D investment, and continue to introduce more competitive silicone products, to meet the escalating demand of customers. At the same time, we will actively expand the international market, strengthen brand building, achieve sustainable development and leapfrog growth, and make greater contributions to the prosperity and development of the industry.

Production Workflow Chart

Production workflow chart of silicone products.

Rubber Mixing

Cutting

Vulcanization Molding

Trimming

QC & Packaging

Warehouse